bathroom products manufacturing

Overview

An end-to-end revolutionary product

Innovative technology is increasingly entering the bathroom products and accessories sector and advanced sanitary devices are becoming usual in our everyday lives. In this line, we received a thrilling project proposal by a leading company specialised in designing and manufacturing bathroom products which was based on developing an entire project to create a totally new product from scratch.

The request we had to meet was offering the whole supply chain and being able to provide all services needed to put the product efficiently on the market. These included the concept and electronics design, mechanics design, plastic parts, manufacturing, packaging and shipping to any subsidiary of the company all around the world.

The technical specifications for this project demanded a high-complexity engineering effort. The main issue was the product needs electricity to work, meaning that if there is a cut of the electricity supply the product must guarantee some minimum functionalities remain active. These are three basic ones: water flush, water refill and another water flush.

But electronics of the product was not complete yet, it also had to include specific technology to ensure connectivity of the device. By being a IoT product, it needed to be connected and controllable from the exterior.

Mechanics was also a crucial matter in the project. All tools and injection moulds had to be designed and manufactured to allow a mass production in compliance with IP65 standard, a critical regulation that certifies the parts are water resistant.

The whole equipment also had to comply with other formal requirements to be marked with the CE seal in order to be commercialised.

The challenge

Electronics running

without power

Solution

Pioneering ideas for a

flawless product

Research carried out at DigiProces Technology Center has been key in this project. Complexity of electronics called for exhaustive designs and tests to comply with both regulations and customer’s requests.

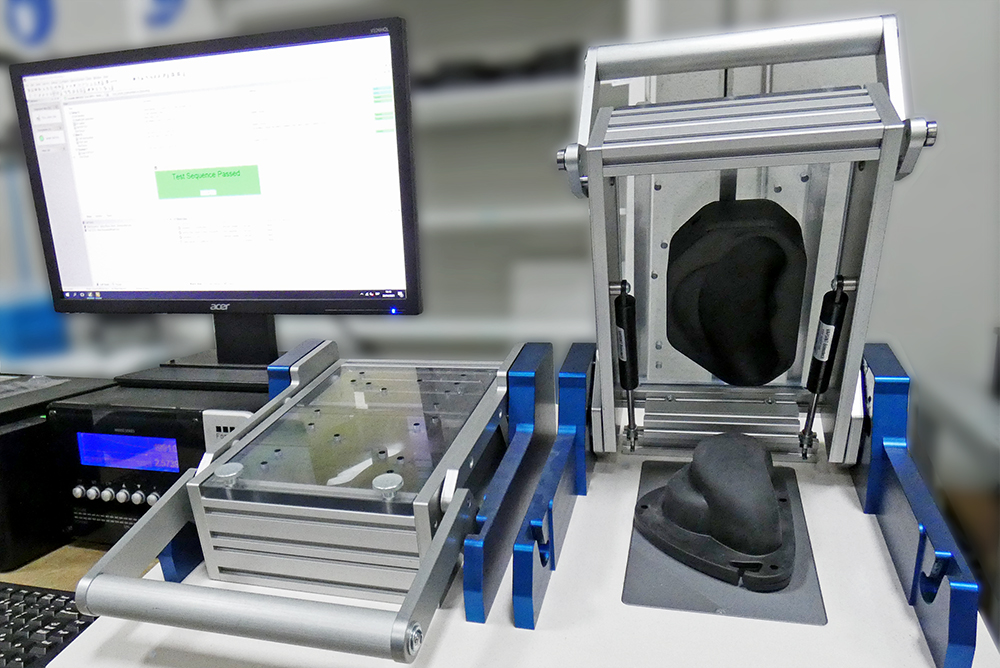

To get the IP65 standard approval we developed plastic enclosures to guarantee water tightness and also test tools to check it offered the correct and desired levels. When a protective casing was not applicable, electronics was protected with epoxy resin by using encapsulation technology.

On the other hand, accurate prototypes and 3D models had to be designed and tested to validate mechanics.

To get the CE certification we performed many internal EMC essays in a long non-stop process in which we put into practice different ideas and solutions that led us to pass the official test in the first attempt.

Our added value

- DigiProces is able to develop comprehensive projects and put a product on the market as quickly as possible. Having the initial concept in mind, we can provide the electronic and mechanical designs, the manufacturing process, packaging and shipping. All services under the same roof

- Our internal EMC lab allows us to accelerate essays and save time and money to pass official standards tests

- Tough challenges like having products to work without electricity can be possible thanks to the research offered by our Technology Center

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona