Nano coating

Ensure protection against dampness and dust for your products

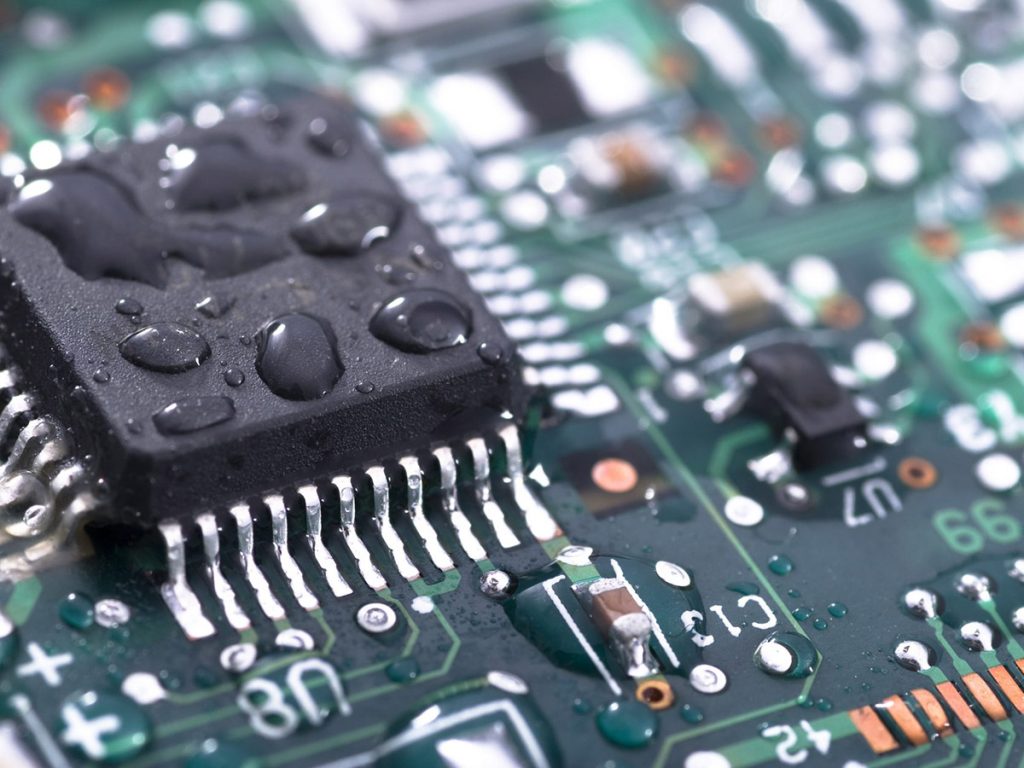

The nano-varnishing process (nano coating) can be performed once the assembly of the electronic product (PCBA) is finished. Thanks to applying this process, an external protection layer is added to your product, protecting it against humidity (hydrophobic) and oils (oleophobic), sulfur in the air, pollution and dirt. It is a protective layer or film of fluoropolymer 0.3 to 1 µm thick (0.5 µm typical) applied selectively accordingly to the topology of the board.

Without such protection, sensitive electronic components can quickly corrode, leading to short-circuits, poor performance and subsequent failure of the equipment.

Chemicals of the product applied in the nanocoating process can be defined as sustainable (non-toxic, non-flammable, with a low global warming index (GWP) and respectful to the ozone layer), which makes it ideal for markets such as bioelectronics or mobile telephony.

The nano coating manufacturing process is performed using specific equipment, properly trained personnel and polymers with precise features.

The nano coating area in our factory is growing due to the increasing demand for coatings to protect electronic circuits, especially against humidity (humid regions, seaside, swimming pools, bathrooms,…).

That is why we have integrated a line with 1 selective coating machine also capable of processing both sides of the electronic product thanks to a turner. The quick drying property of the polymer allow it to avoid oven curing, thus achieving very good process takt times.

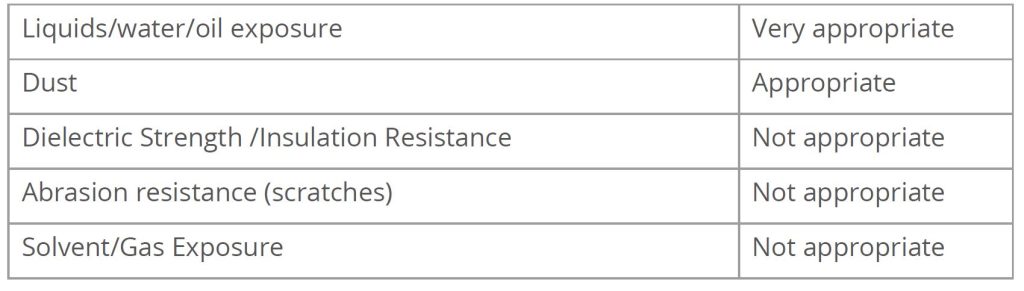

PROTECTION

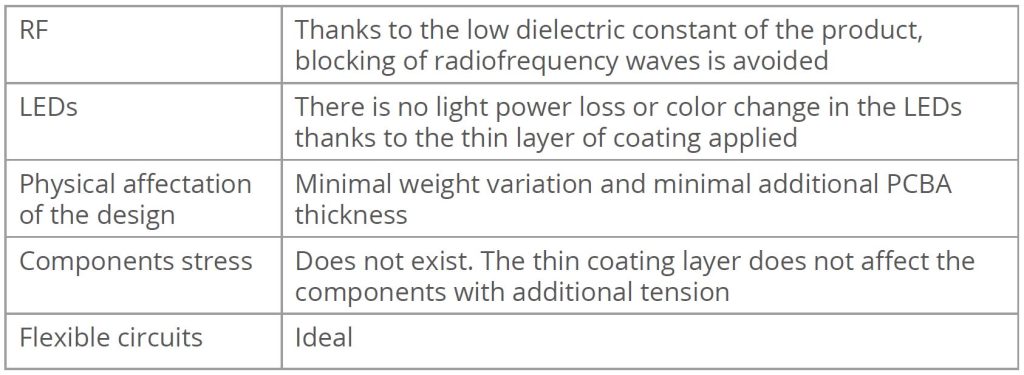

COATING PROCESS AS A RESTRICTION IN THE DESIGN

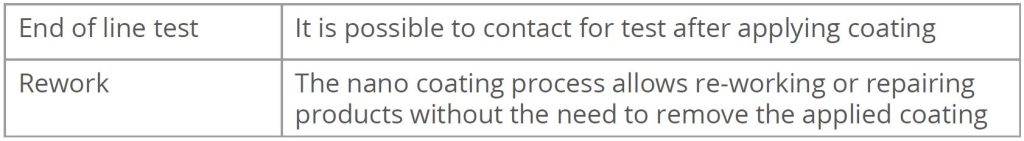

COATING PROCESS AS A RESTRICTION IN THE PRODUCTION PROCESS

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona