Systems Integration & Assembly

Delivering high-reliability assemblies that combine electronics, mechanics and complex interconnections

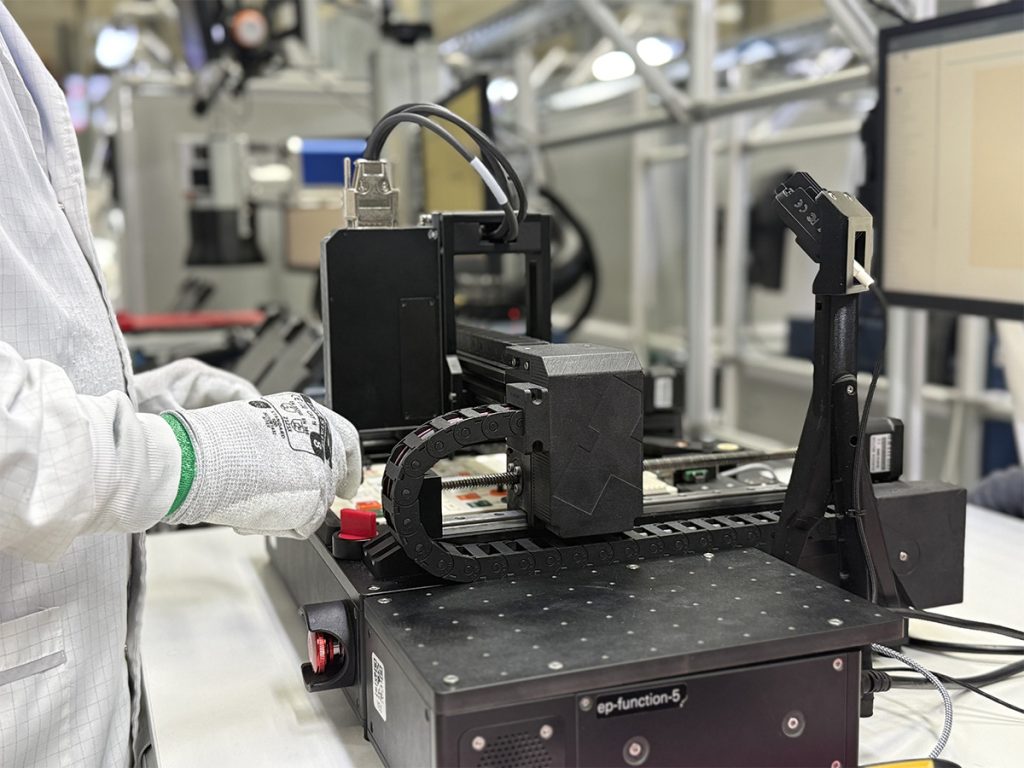

At DigiProces we provide complete System Integration & Assembly services for customers who require more than PCB manufacturing. We specialise in building electromechanical assemblies, wiring systems, control panels and integrated test modules where quality, traceability and repeatability are essential.

Our approach is based on the same discipline and process control we apply to our PCBA operations, extended to the world of mechanical and system-level integration.

What we deliver

Electromechanical assembly

We build the complete electromechanical platform of your product: chassis, backplates, panels, precision brackets and integrated subassemblies. We coordinate key structural elements — PCBs, power supplies and housing and integrate electromechanical devices such as fans, relays or motors to create fully functional systems.

Wiring harness and interconnections

We design and manufacture the product’s “nervous system.” Cable networks link PCBAs to supplies, sensors, user interfaces and peripherals. We cut, strip, terminate, crimp, route and label each wire according to the drawings and IPC/WHMA‑A‑620 guidelines, ensuring signal integrity and repeatable routing discipline.

Integration of industrial connectors

We integrate industrial and military connectors from all major families, from high‑density modules to high‑power interfaces. We work with Virginia Panel, Mac Panel, Harting, Phoenix, Amphenol and other brands used in automation and test equipment, guaranteeing signal integrity and serviceability.

First Article builds with full traceability

At the prototyping stage we work strictly to the drawings and Bill of Materials (BoM), the product’s “DNA”. We verify BoM accuracy, identify deviations and document manufacturability issues early, preventing shortages and integration delays and feeding pre-Production improvements before serial manufacturing.

Transition to production

Once the First Article is approved, we develop the supply chain and manufacturing workflow for series production. We qualify suppliers, plan material kitting and optimize labour to maintain quality and repeatability while reducing lead times and cost per unit.

Quality assurance

Our layered quality system combines visual and mechanical inspections, continuity tests, torque validation and structured functional tests. We align with IPC‑A‑610 for PCBA, IPC/WHMA‑A‑620 for wire harnesses and IPC‑A‑630 for enclosures, and integrate client‑specific requirements such as CE.

How we work

1. Engineering & Documentation intake

We review drawings, BoMs, interconnect lists, cable schedules and test procedures. Precise documentation is the foundation for quality control and cost estimation. We ensure the BoM includes physical dimensions, regulatory requirements and special instructions

2. Controlled assembly environment

System builds are performed with the same discipline as our PCBA line: ESD protection, material traceability, documented workflows and rigorous routing control. We have controlled areas for mechanical assembly, wiring and software loading to guarantee repeatability and connector integrity.

3. Manufacturing engineering (optional / on request)

For recurring production, our manufacturing engineering team develops detailed work instructions, optimizes wiring routes, qualifies alternative suppliers and proposes cost‑reduction scenarios. First Article learnings and pre-Production improvements are treated as part of process readiness.

4. System integration & test

We install the PCBA and mechanical components into the housing, connect harnesses, load firmware and perform system‑level functional tests. Client‑supplied test procedures are executed step by step to verify reliability, durability and safety; results feedback into engineering before ramp‑up.

5. Transparent supply chain

We manage the procurement of parts from client‑specified vendors or suggest validated alternatives when allowed. Consolidating mechanical, electrical and testing needs into a single integration partner reduces supplier sprawl and associated risks

Certifications and compliance

- ISO AS9100, ISO14001

- IPC-A-610, IPC/WHMA-A-620 and IPC-A-630

- Process compatible with NADCAP, ITAR and MIL-STD workflows

- Component-level traceability and the ability to icorporate regulatory requirements such as CE, RoHS or UL

Why DigiProces?

- Demonstrated experience integrating electronics, mechanics and wiring for demanding sectors

- Process discipline inherited from our PCBA background and applied to system level integration

- Full traceability and a structured First Article methodology that identifies design and manufacturability issues early

- Ability to scale from prototypes to hundreds of units per year, with flexibility tailored to demand

- Customer focused, risk mitigating approach—consolidating assembly and supply chain, avoiding CAPEX investments, accelerating time to market and allowing your engineers to focus on innovation

Looking for a reliable European partner for your systems integration?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona