Counterfeit

Counterfeit

Defective electronic components are an issue for several obvious reasons:

- A risk of injury or even death in some sectors (medical, military, automotive)

- Risk of fires due to short-circuits

- Altered product performances

- High costs and revenue loss for the industry

Check the components

The first thing to do is to carry out a series of checks on electronic components to make sure they are undamaged (AOI, electric, impedance tests, micro-sectioning or X-ray inspections).

By measuring the height, length and width and comparing them to the specifications of the manufacturer, we can also deduce whether the component is counterfeit or not.

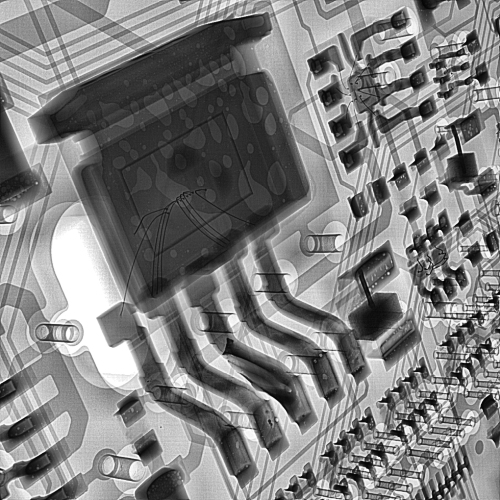

An X-ray machine can provide a detailed and non-intrusive inspection of dies and solders and also detect delamination. Then all we need is comparing to the manufacturer’s specifications to check the component is genuine. In the same vein, an electric test on suspicious components will give a tolerance that can be compared to manufacturer data. If the difference is too significant, further investigation is required.

Identify blacktopping

Widely used by counterfeiters, blacktopping consists in hiding the original serial number and printing a different marking over it to deceive the purchaser. This can’t be detected by the naked eye, but an experienced viewer can detect the fraud under a microscope. Acetone can also be used to remove the fake marking.

Decapsulation

As a last resort, the dismantling of the component implies an intrusive and therefore destructive operation. However, this is really the last solution to see what is inside a component if none of the other tests were able to prove its authenticity. A powerful microscope is used to inspect the manufacturer’s marking, the defective parts, the font and the authenticity of serial numbers.

Reduce the risks

Purchasing directly from the manufacturer seems to be a reliable way of reducing the risk to a minimum. Multiplying the number of intermediaries reduces transparency and increases risk.

Know your suppliers Le GIDEP or Government – Industry Exchange Program is a database that lists the components suspected by North American industry to be counterfeits.

Other aspects need to be checked to make sure your supplier is honest:

- Do your suppliers reveal the list of its providers to offer maximum transparency?

- Do they comply with the international AS6081 standard on fraud and counterfeit electronic components?

- Do your suppliers make sure the minimum tests required by the AS553A standard are carried out?

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona