Traceability: all the information at our fingertips to improve each process

Traceability is the essence of factory digitalization. It consists of collecting data on everything that happens to the product during the production process to later analyze them and improve both the efficiency of the process and the quality of the product.

Do you want to know how we implement our traceability system in DigiProces?

Thanks to the implementation of traceability in the factory, it is possible to clarify “when and where was produced what and by whom”. Its main benefits are the following:

- Security. In the event of any failure of the product in the market, DigiProces, as the manufacturer, can quickly present data on the raw materials and the production process that affect the product in question.

- Compliance. DigiProces can ensure that the production process followed to manufacture each product is in accordance with what is specified in the latest version of the documentation approved for its manufacture.

- Conformance. DigiProces can prove that the quality standards required for each product/customer/market have been followed.

- Quality. DigiProces can find the root causes of problems that arise in the production process in an agile and easy way, which directly means an improvement of product quality. At the same time, the image of our customers is protected thanks to the fast and reliable response of DigiProces.

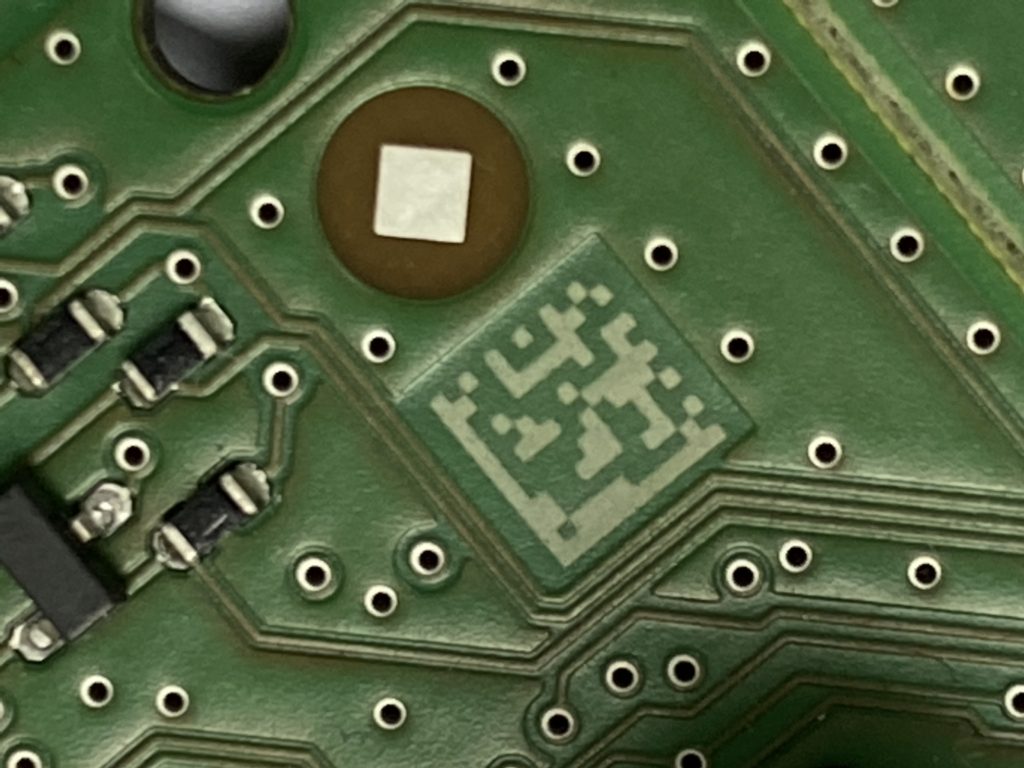

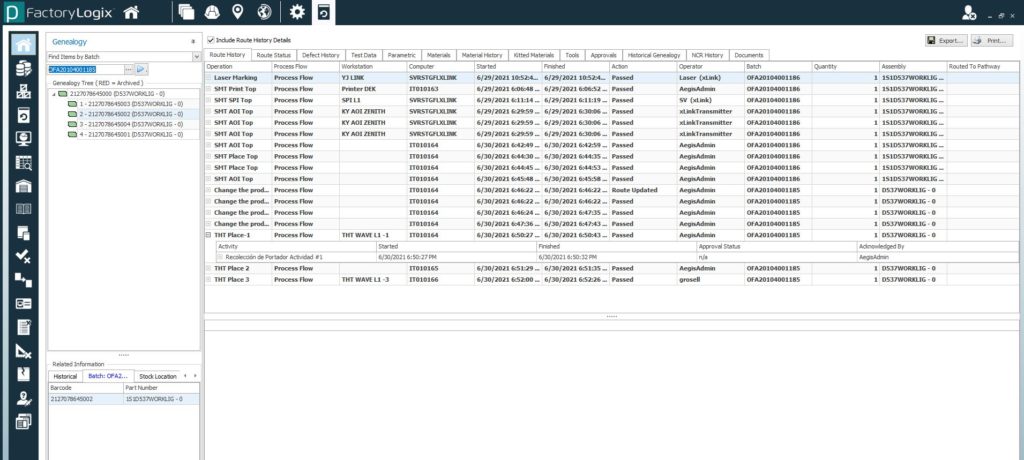

MES: FactoryLogix

DigiProces uses Aegis MES (Manufacturing Execution System), FactoryLogix, as a powerful tool for manufacturing control. FactoryLogix is responsible for collecting data for traceability, from reception of raw materials to the shipment of the product, going through all the manufacturing processes: kitting, SMT, THT, coating, Box Build, test and packaging.

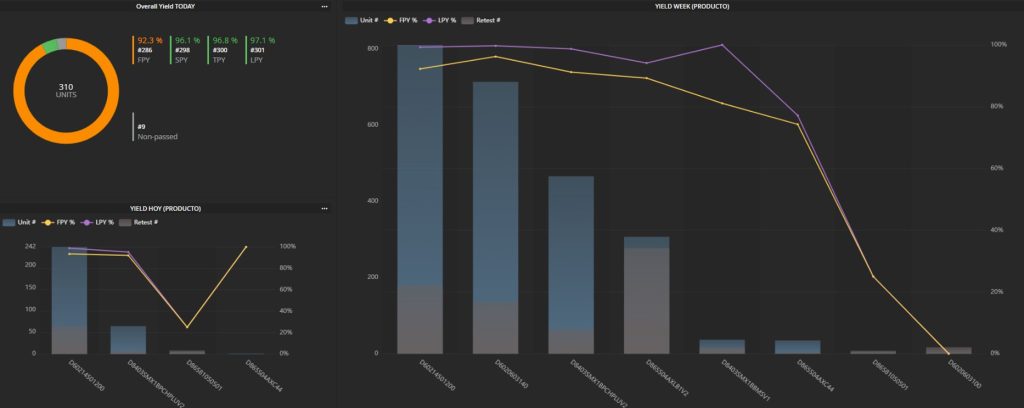

Test Data Management system

DigiProces has a powerful software tool for the analysis and management of data from production test stations (Production Test Data Management System). With this platform, our customers can immediately have the production performance of their products (yield), as well as process quality indicators such as Cp, Cpk and population distribution. These data are obtained from the final test stations thanks to a functional test of the finished part.

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona