Overview

How to face the current electronics storm efficiently

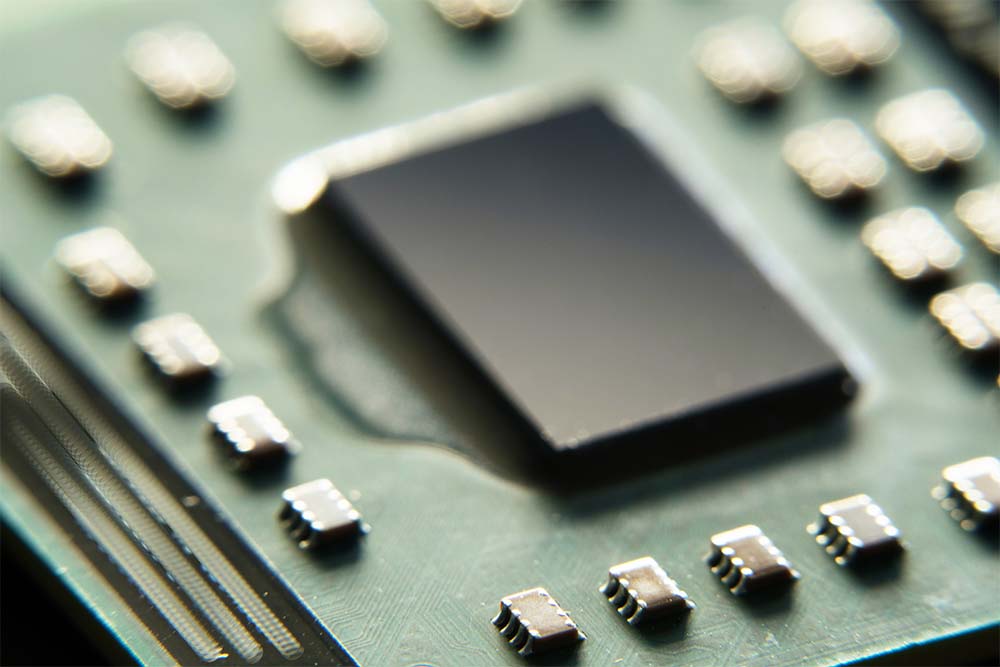

The global semiconductors shortage is shattering the plans of many companies. This atypical situation forces us to look for alternative formulas to continue manufacturing in spite of not having availability of very critical parts for the product. In this context, the speed and the efficiency with which we manage to handle this matter will determine our production capabilities and show our strengths to our customers.

One of our customers, a leading electric vehicle manufacturer, needed to have a serious supply problem solved, so we had to put hands on work to offer an appropriate alternative.

Suddenly, and with a very short reaction time, the manufacturer of the main microcontroller of the BMS (Battery Management System) circuit announced that the agreed delivery schedules could not be met and the components required would not be available until 52 weeks later. This sudden news would cause our customer to stop their vehicle production lines within 3 months from the announcement if we could not find a solution.

The Challenge

Finding suitable alternatives

for critical parts

Solution

Redesign of the product with a new microcontroller

At this point, we decided to look for an alternative microcontroller on the market. But there was an essential requirement, there should be a quantity enough to continue to manufacture for the 52 weeks remaining until we receive the original part. Once we found it, we bought the whole batch needed for this period and when we had it already in our warehouse our engineering team started with the redesign of the product to adapt it to the new microcontroller.

Our added value

- Quick reaction time. In just two months we had to redesign the hardware and firmware, pass the EMC tests and complete the corresponding endurance tests so that the product could go on the market again

- Intensive and close cooperation with the customer. Our engineering departments and the OEM manufacturer created a new version of the product including the new microcontroller in a record time

- Reliable time to market. Our custom-built solution allowed to deliver the product on time and prevented our customer from stopping the electric vehicle’s production line

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona