How are production standards defined at DigiProcesProduction standards are...

What is DigiProces forecast for this yearWe live in times of high uncertainty...

From the initial idea to delivery to the customer DigiProces offers global...

The new Electromagnetic Compatibility (EMC) laboratory of DigiProces is already...

Electronics is the backbone of innovations in the healthcare technology sector...

DigiProces is already manufacturing in series electronic components integrated...

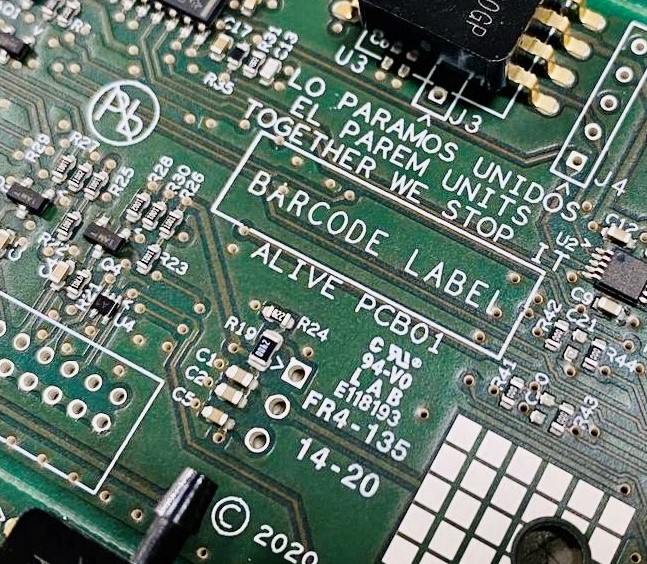

After the publication of Royal Decree-Law 10/2020, dated 29 March, from...

Innovation and technology play a key role in the health system Thanks to...

Next June we will inaugurate a new laboratory for precertification With this...

We will be at electronica 2018 introducing our evolution to Smart Factory...

We are continuously investing in new state-of-the-art equipment for our...

With increasingly complex PCBAs, the test cycle time is a fundamental factor...