Box Build Assembly

The complete product assembly

This type of assembly is reasonable because handling PCBAs manually require a high level of accuracy and reliability, and thus it is better to make the assembly of the final product in the same environment where the PCBA was born.

Outsourcing a box build assembly offers several significant advantages for companies looking to enhance their operations and optimize their product development process:

- The outsourcing process can lead to substantial cost savings. If a set up for an in-house assembly cell to finish the product is needed, it would require a significant investment in infrastructure, equipment, tooling, training and personnel. Your manufacturing partner already owns these resources in place, that will allow to avoid upfront expenses and ongoing maintenance costs.

- A proper assembly process ensures compliance and product safety. Since the EMS is specialized in providing end-to-end manufacturing solutions, their know-how guarantees that your product is assembled and integrated efficiently, according to the industry standards and best practices.

- By outsourcing the box build assembly, you can focus on your core competences and company goals, allowing you and your team to concentrate on the value-added activities that are driving your business.

- The EMS is equipped to absorb some level of fluctuations in production volume. This scalability ensures that your needs are met, regardless of the market demand, without the need for constant adjustments to your own production capabilities.

- Instead of having 100 different Internal Part Numbers (IPN) in your ERP system, you will just have the 1: a ‘one-stop solution’. As a result, you will obtain cost savings on individual parts, the overall subassemblies, as well as on the logistics involved.

- With the right EMS partner you are ensured thorough quality control processes. This helps prevent defects and reduces the likelihood of costly recalls or rework.

- Partnering with a good EMS as a box build provider can help you reduce supply chain risks. They have deep experience in managing suppliers, handling issues, navigating potential disruptions, safeguarding your production timeline, and reducing exposure to unforeseen challenges.

Stick to an EMS that can be dedicated to your project from start to finish. Find a box build electronics manufacturer and keep it all in one place.

An EMS that stands out in the box build assembly process will need to prove proficiency in the following matters:

Sustainability

The electronics industry is under increasing pressure to address environmental concerns, and Box Build Assembly is not exempt from this challenge. The EMS will need to focus on energy-efficient processes and recycling initiatives to reduce the environmental impact of the manufacturing process.

Supply chain

Several sub-assemblies will go into your finished product. It means that challenges in sourcing components for the assembly process of the product will appear. Manufacturers will need to navigate issues such as component shortages, geopolitical factors and disruptions, highlighting the importance of resilient supply chain management strategies.

Robust testing strategy

Testing is a key part of product reliability and assures that your product will withstand daily use. Your box build assembly should include comprehensive testing and inspection to identify potential issues and deviations (Production Test Data Management).

Packaging and labeling

Proper packaging and labeling is yet another major step in box build assembly, including everything from the conveniently sized box, foam or other inserts, up to terminology, symbol and logo usage, and of course barcoding.

Final inspection

Before shipping, a final inspection is conducted to verify that the product aligns with specifications and customer requirements.

Aftermarket services – Repair

Ensuring products can be serviced, maintained and replaced in local facilities rather than being flown around the world will be a major plus in this age of higher sustainability.

Incoming Quality inspections

Mechanical parts and enclosures will sometimes require unique dimensions or special spacing, routing or mounting. They could potentially not only provide protection against external elements but also contribute to the overall aesthetics of the final product, meaning that quality control is a key step within the box build process.

Assembly process

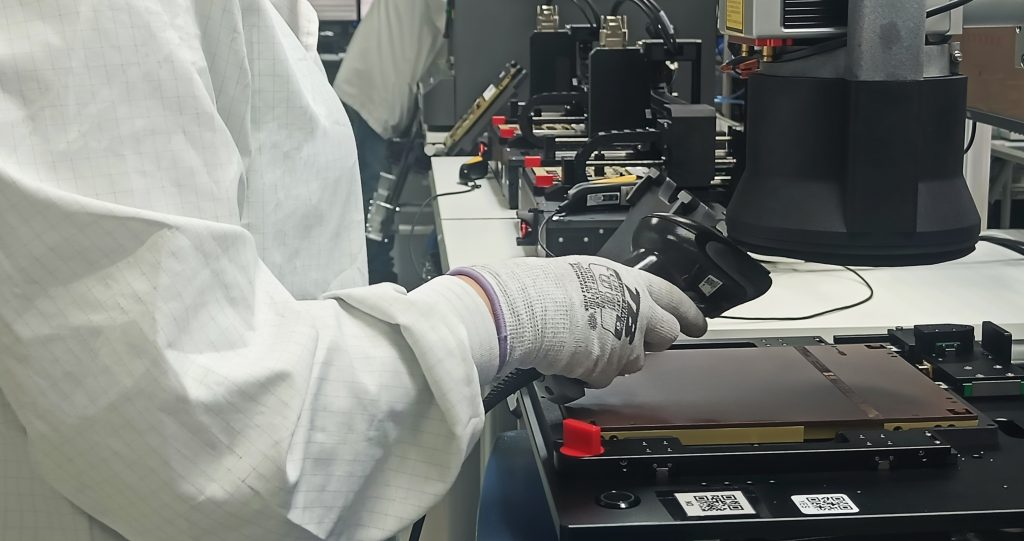

We design dedicated lean lines to provide a bespoke manufacturing environment for highly configurable and complex box build products. These lines are based on 2 to 6 process steps and fast changeover concepts that are able to deliver a responsive solution when demand is dynamic, but lead-times are short.

Skilled technicians that are recurrently trained to excel within the production cell tasks are assembling the components into the enclosure following precise work instructions. Maintaining this expertise can be a challenge for manufacturers.

Control over the manufacturing process

Tracking the process thanks to digital work instructions, real-time monitoring and data analytics throughout the box build assembly process is essential to improve the productivity of the cell, as well as for potential quality issues. Each product manufactured needs to match the documentation package and the production parameters used. This documentation helps in troubleshooting and future improvements.

Outbound Logistics

The EMS is able to deliver finished products directly to end users all around the globe.

Entrusting the assembly process to DigiProces will free up your valuable internal resources. It will also allow you to profit from our knowledge and capabilities. The potential for using an existing reliable network, our cost-efficiency and the reduction of logistical tasks underscore the advantages that outsourcing the box build can offer.

Box build assembly operations at DigiProces have grown out of the need to provide our customers with a complete EMS solution. We are dedicated to developing customized box build processes which are unique to the each customer’s objectives, using lean manufacturing techniques in all operations to come out with high quality electronic box assemblies at a reasonable cost.

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona