Conformal Coating

Ensuring reliable performance of today’s electronics

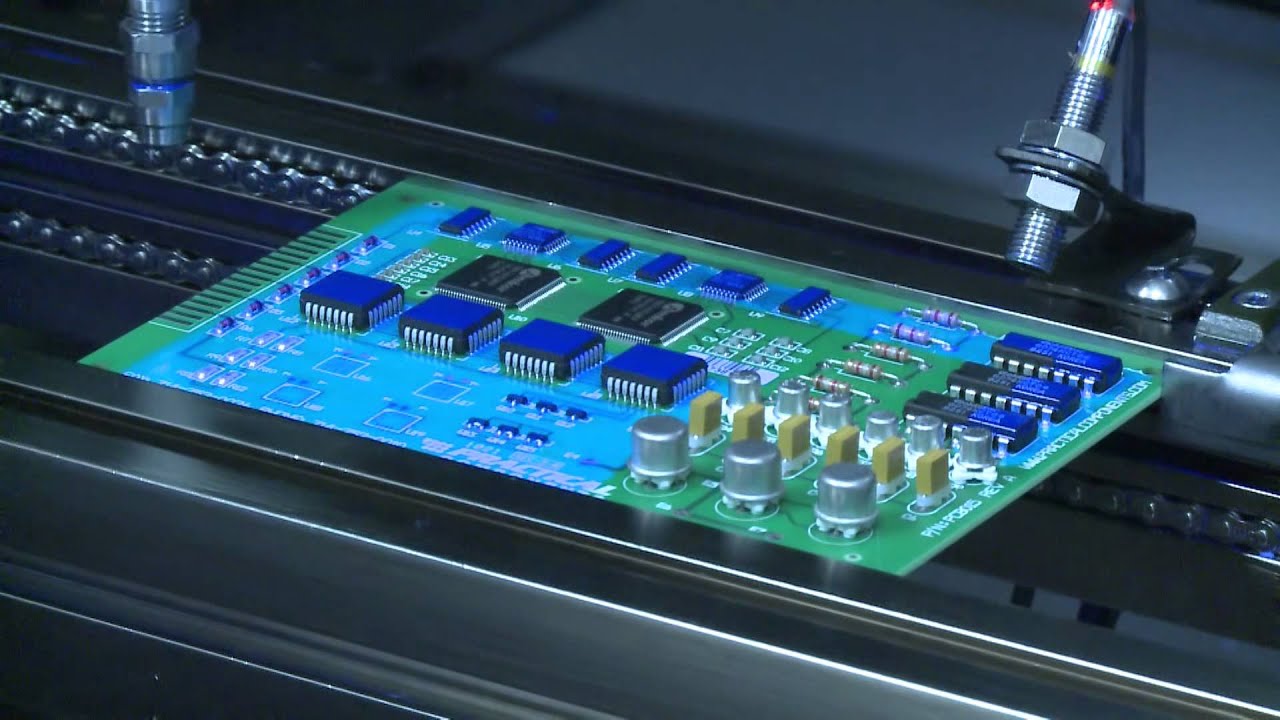

A conformal coating can be applied to provide your PCB assembly with harsh environment protection including fortification against dust, moisture, chemicals and extreme temperatures. This is a protective coating or polymer film 25-75µm thick (50µm typical) that ‘conforms’ to the circuit board topology.

By being electrically insulating, the conformal coating maintains long-term surface insulation resistance (SIR) levels and therefore ensures the operational integrity of the assembly.

It also provides a barrier to airborne contaminants in the operating environment, such as salt-spray, thus preventing corrosion.

Our factory’s conformal coating area is constantly growing due the increasing demand of this PCBA finishing by OEMs. That is why we have integrated functional testing and conformal coating together in one line with 2 selective coating machines and a flipper to coat both sides. Thanks to this setup we have hugely increased the takt time of this process.

Depending on the type of material, thickness and coverage required, conformal coating could also be applied manually.

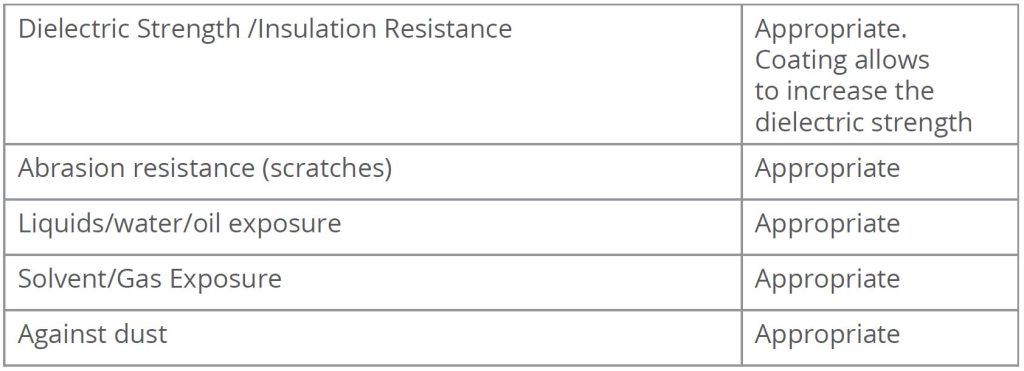

PROTECTION

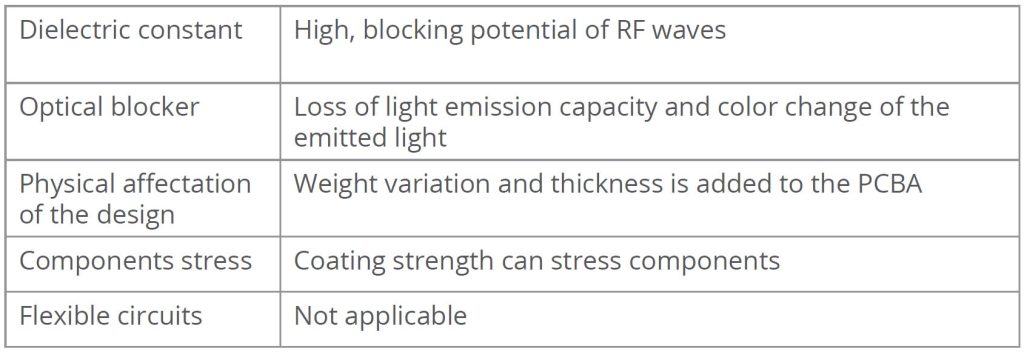

COATING PROCESS AS A RESTRICTION IN THE DESIGN

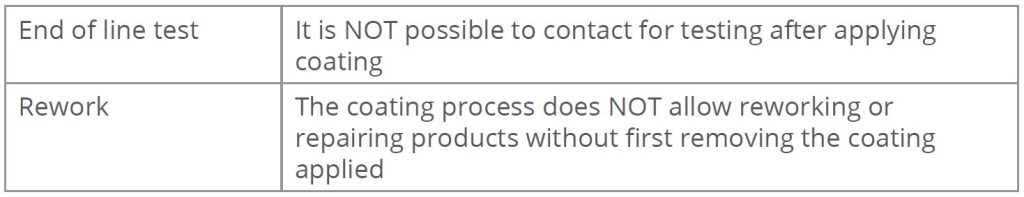

COATING PROCESS AS A RESTRICTION IN THE PRODUCTION PROCESS

Looking for a business opportunity?

Address

Solsonès, 87 – P. I. Pla de la Bruguera

08211 Castellar del Vallès. Barcelona